PLASTIBOR

Gorlan Group company dedicated to transforming plastics with injection processes since 2003.

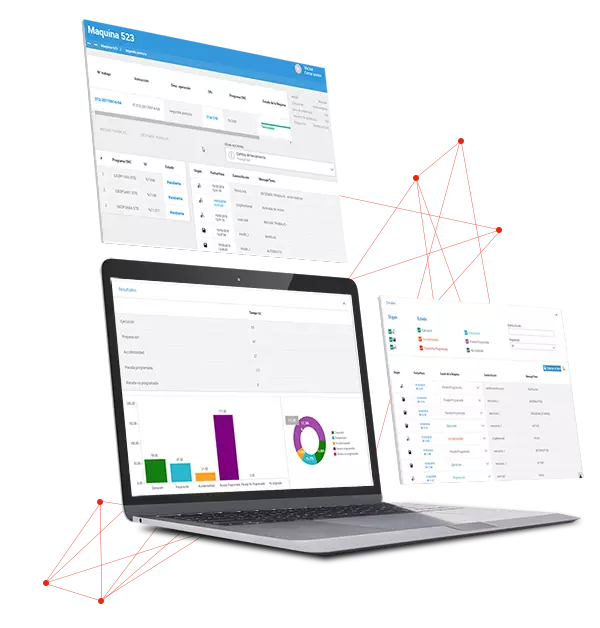

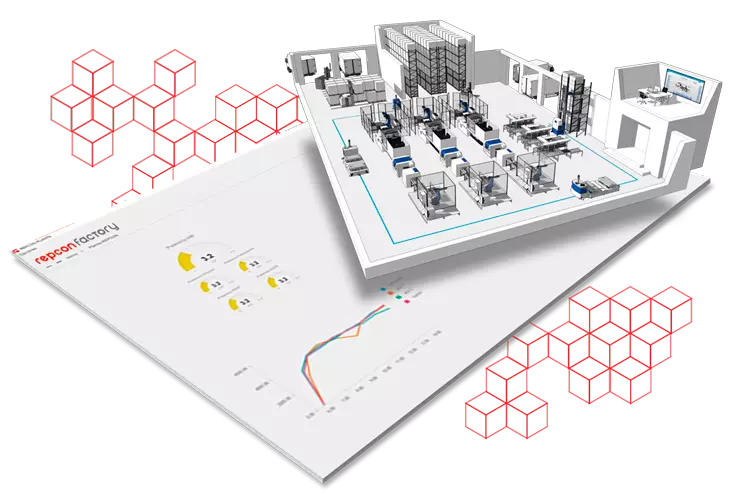

repcon Factory is the solution that enhances process efficiency in plants, simplifying real-time data collection, modelling, visualisation of progress and production line results.

Thanks to its multiple functionalities, it interconnects the entire factory: from machines and products to people and systems that allow them to make the most appropriate decisions with precise up-to-the-minute data.

Satisfy all your plant’s management needs to achieve not only control over operations, but also precision in the data obtained, allowing for efficient subsequent use.

repcon Factory contributes to process automation, facilitating all plant communication flows more efficiently between users with all the information necessary to do so.

The digital factory, as with other industrial and management operations, is inexorably heading toward the paperless era. Thanks to repcon Factory, we can manage employee and operator notifications as well as the documentation necessary for each process in a single place, to mention only a few of its functionalities.

repcon Factory offers a significant advantage over traditional monitoring systems: it has online technology, allowing it to be used on any device, so it can be used in any part of the production plant.

Solution that simplifies the collection of data at the plant in real time as well as the modelling and viewing of the production lines. Facilitates integrating the information obtained from the machines with the management applications (ERP, MES).

Conventional monitoring systems are not equipped with web technology, so they are limited to use within the plant.

Applying production directly from the machine.

Generating erroneous, unreliable data as a result of the data collection process.

Wasting operator time on administrative tasks.

Latency in response times due to lack of real-time information.

Difficulties connecting to machines from different manufacturers and those with different protocols.

Automation and control solution at the plant focussed on information management of the production process: manufacturing orders, personnel, incidents and alerts. Open platform, ERP management, planners, configurators, etc.

Late incident management.

Lack of materials in the plant.

High dedication of personnel to logging data into systems.

Manual logging, which can lead to erroneous, unreliable data.

Wasting operator time on administrative tasks.

Procedures articulated based on inefficient hardcopy forms.

Latency in response times due to lack of real-time information.

Discover the solution that enhances plant production process efficiency.

We custom design services for each customer to manage their IT infrastructures. Our large team of professionals has the technical skills and certifications in the major technologies on the market.

Gorlan Group company dedicated to transforming plastics with injection processes since 2003.

The Gorlan Group’s automation plan for various plants continued with the implementation of repcon Factory, in this case in its Plastibor factories. Dedicated to transforming plastics with injection processes.

In-plant work control application.

Masa specialises in manufacturing finished metal parts equipped for the aviation industry.

Digital Transformation of Bossar Packaging.

Founded in Barcelona in 1992, Bossar Packaging, S.A. has positioned itself as a global leader of horizontal packaging machine design and manufacturing.

ZIGOR is a global leader in next-generation power electronics equipment,

particularly for integration into renewable energy systems. Its equipment

enhances grid regulation and stability, ensuring a reliable, efficient,

and high-quality power supply for critical industrial processes that require

uninterrupted power.

ZIGOR has a clear international focus, with projects developed across

four continents, where the quality of customer service is fundamental.

Sergio Pérez Rubio

Industrial Manager

Plastibor

Igarki San Millán

Head of IT

Mecanizaciones Aeronáuticas, S.A

Agustí Mir

Xabier Etxenike

CCS – Product Marketing Manager

Danfoss Power Solutions

The Path Toward the Digital Factory. A complete course in which you’ll discover the keys of Industry 4.0 and the steps to pave your way toward the digital factory.

Digitise and Enhance Injection and Extrusion Processes.

MES System Goals: Reduce Costs and Boost Plant Efficiency.

Technology evolves so fast and continuously that many companies have a hard time incorporating them into their value chain at the necessary pace. Improved efficiency in production processes, real-time data collection that […]

Nowadays, manufacturing companies face huge requirements. They need to reduce costs while also boosting productivity. All while guaranteeing quality 100% of the time […]

In an increasingly competitive world, where cost savings and increased productivity have become the only path to follow […]

Manu Vilchez

Head of the repcon Factory unit at Semantic Systems.

Agustí Mir

Director of support processes, finance, HR, IT and communications at Bossar

Packaging.

Juan Antonio Gómez

Head of consulting for the digital transformation at Semantic Systems.

Tomas Iriondo

Managing director of GAIA.

DISCOVER ALL THE LATEST FROM SEMANTIC SYSTEMS

repcon Factory is the solution that enhances plant production process efficiency.

How long does it take you to prepare a quote and send it to your customers?

We live in a world in which product customisation is essential.

SMEs are interested in solutions to improve relationships with customers and drive more demand, faced with restrictions on large events and fairs.

At Semantic Systems we share tech content including: IT Systems and Infrastructures, Cybersecurity, Digital Transformation, Industry 4.0, Digital Twins, etc.